Technology

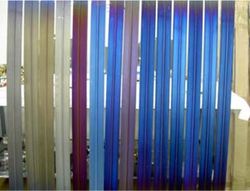

Selective covers are applied in the most advanced PVD vacuum chamber and consist of composites of titanium and other metallic and gaseous ions. Selective covers have high coefficient of absorption, low coefficient of reflection and emission, high thermal stability and corrosive.

With our equipment we can produce selective PVD Selective covers on one or both sides of the absorber as well absorbers flat plate and CPC collectors for absorbers with maximum stability at high temperatures.

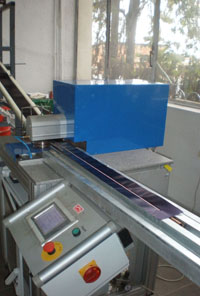

Solar Tubes has a cutting edge ultrasonic machine for ultrasonic welding:

copper wings with Selective covers with copper tube

aluminum with wings Selective covers with copper tube

aluminum with Selective covers wings with aluminum tube

aluminum or copper wings with Selective covers ultrasonic welded aggregate copper or aluminum tubes

With These procedures Solar Tubes has potential to produce as copper flat-plate collectors and aluminum flat-plate collectors and a combination of aluminum-copper flat-plate collectors.

Solar Tubes produced as standard flat-plate collectors and flat-plate collectors with original structures absorbers which increases the coefficient of efficiency of the collector.

The vacuum panels that are listed in the production assortment Solar Tubes used several types of U - type absorber where the heat transfer from the surface of selective coating the vacuum tube to the circulating medium in vacuum tube has a very high coefficient of heat transfer which are additionally ratio increases the efficiency of vacuum tubes.

Ultrasonic welding of copper tube with copper foil

Ultrasonic welding of copper foil with copper pipe collecting Ô 22 mm

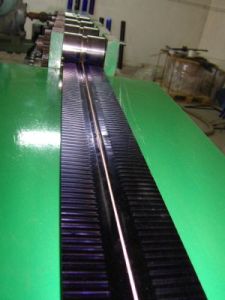

Ribbing of the absorbers

Absorber of extruded aluminum

Application of selective coating

Application of selective coating

© Copyright Solar Tubes 2010